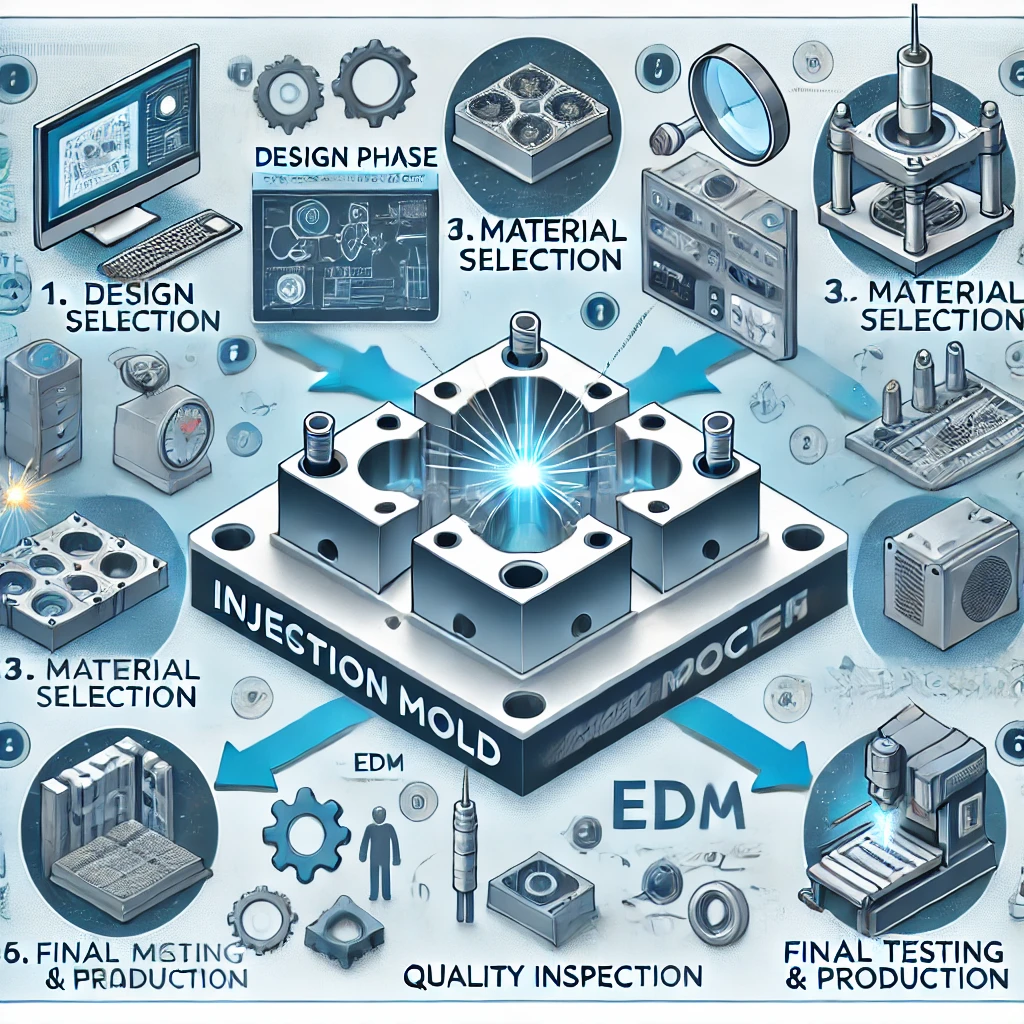

Launching a new product as a startup is an exciting journey, but selecting the right injection mold maker is a critical step that can impact product quality, cost, and time to market. Here’s what startups need to ensure when making this decision.

1. Experience & Expertise in Your Industry

Not all mold makers have experience with every type of plastic product. Ensure your chosen manufacturer has a proven track record in your specific industry, whether it’s consumer goods, medical devices, or automotive parts.

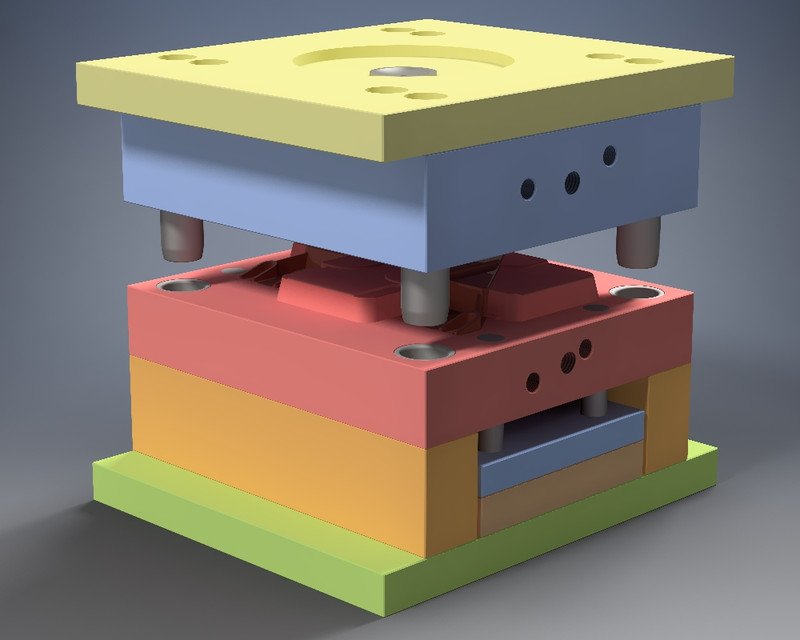

2. Material Selection & Quality Standards

The durability and functionality of your product depend on the quality of materials used in mold making. Ask about the mold materials they use (e.g., steel, aluminum) and verify if they meet industry standards like ISO 9001 certification.

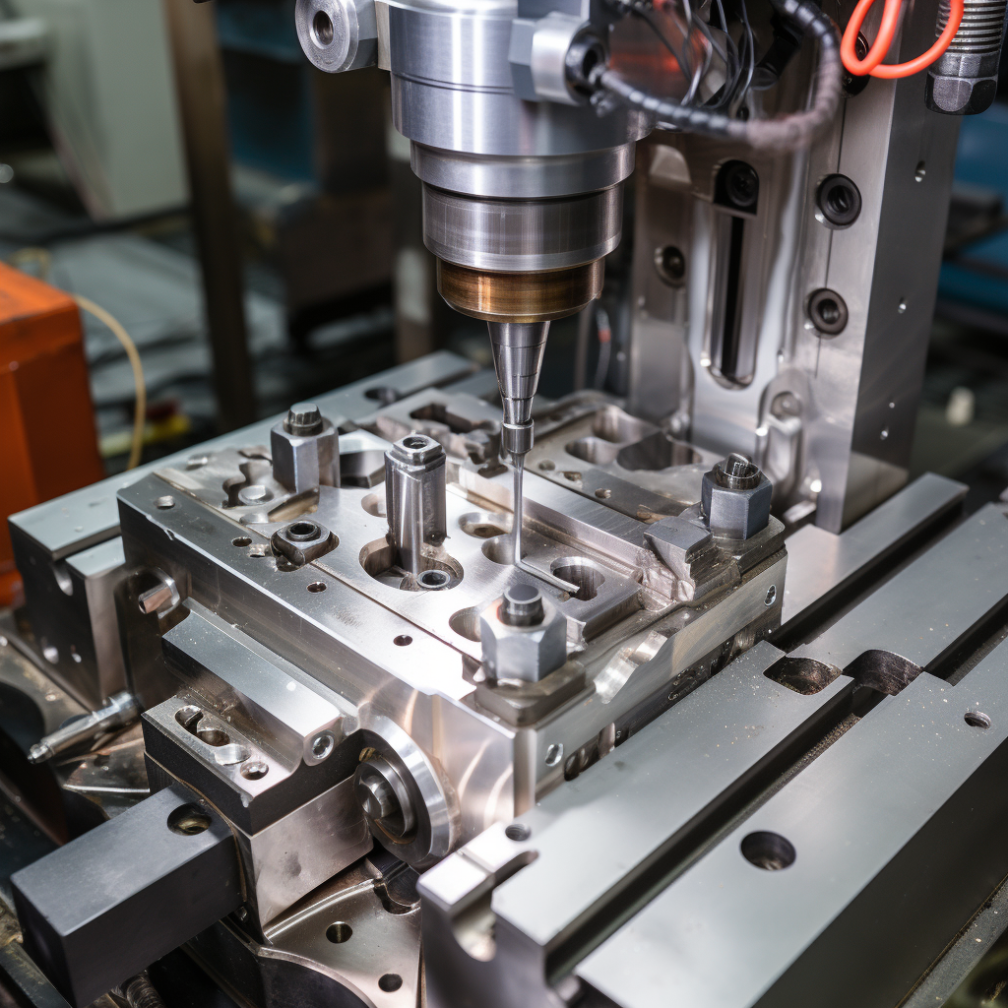

3. Precision & Technology Used

Modern manufacturing relies on high-precision CNC machining, EDM, and CAD/CAM software. Ensure your mold maker utilizes state-of-the-art technology to produce highly accurate and defect-free molds.

4. Cost vs. Long-Term Value

While cost is an important factor, don’t compromise on quality. A cheaper mold might lead to higher maintenance costs and production delays. Consider the total cost of ownership, including maintenance, modifications, and expected mold lifespan.

5. Prototyping & Testing Capabilities

Before committing to large-scale production, verify if the mold maker offers prototype molds or low-volume testing. This step helps refine your product design and prevent costly errors in mass production.

6. Lead Time & Production Speed

Startups need to bring products to market quickly. Ask about the manufacturer’s turnaround time and whether they can scale production to meet growing demand.

7. Communication & Support

A responsive and collaborative partner is essential. Ensure your mold maker offers clear communication, project updates, and post-production support.

8. Compliance & Certifications

Ensure the mold manufacturer follows regulatory standards, especially if your product requires FDA compliance, UL certification, or RoHS standards.

Final Thoughts

Selecting the right injection mold maker can make or break your startup’s success. Prioritize quality, experience, and support over just cost, and you’ll ensure a smooth production process for your plastic products.

🚀 Need expert mold manufacturing for your startup? Contact Onemold for reliable, high-quality solutions tailored for startups!